Materialise – Innovators you can count on

Materialise incorporates more than 25 years of 3D printing experience into a range of software solutions and 3D printing services, which together form the backbone of the 3D printing industry. Materialise’s open and flexible solutions enable players in a wide variety of industries, including healthcare, automotive, aerospace, art and design, and consumer goods, to build innovative 3D printing applications that aim to make the world a better and healthier place. Headquartered in Belgium, with branches worldwide, Materialise combines the largest group of software developers in the industry with one of the largest 3D printing facilities in the world.

27 Years of Innovation: A History of Materialise Pioneers

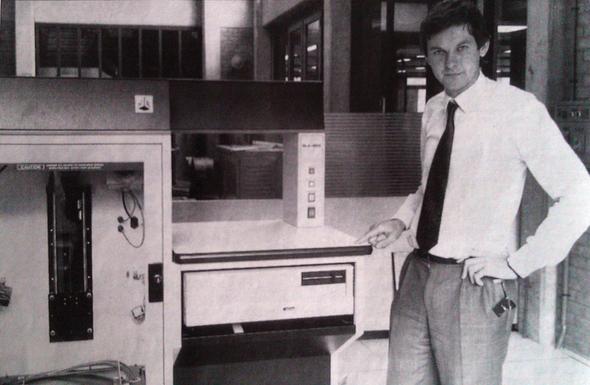

To those in the 3D printing industry, Wilfried Vancraen is a familiar name. More than 27 years ago, Fried saw his first 3D printer ever – and it made such an impression on him that he and his wife Hilde ended up starting their very own company called Materialise, pooling all their savings together to acquire just one Stereolithography printer. Materialise has come a long way since then, and on the 27th of September, Fried had the honor of being inducted into the TCT Hall of Fame along with four other industry leaders who have made significant contributions to the development and innovation of 3D Printing. In this blog post we take a look at Fried’s journey from young engineer to respected industry pioneer.

Picture a small office in the 90s: this was before the internet, before smartphones – even getting information from one computer to another required the use of the iconic, now defunct, floppy disk. Many of these early days were spent trying to overcome technological hurdles. It was in solving these problems that some of our main products were created: Materialise Magics software was born because it was extremely difficult for 3D printers to read computer files.

Fried hired a student – Johan Pauwels, now Executive Vice President – to develop software which would enable them to transform digital 3D files into a format which the printer would be able to print. Then came the first official employee of Materialise, Philip Schiettecatte, now a Senior AM Engineering Consultant with unmatched experience for our Manufacturing customers. Hilde, now the Executive Vice President of Materialise Medical, took care of the administrative side of Materialise, a task Fried disliked, but which was very necessary for the sustainability of the company

From the very beginning, Fried recognized the benefits the technology could bring to the healthcare sector. Due to his background as a biomedical engineer, the link seemed obvious. Starting from CT image data, Bart Van der Schueren, a research assistant at the University of Leuven (and now CTO of Materialise), started printing out patient-specific anatomical models. His early experiments led to the creation of Materialise Mimics, and from the very first days of the existence of Materialise Fried and his fellow pioneers were in search of meaningful applications for 3D Printing. The presence of innovators in the company from the very first moment is an indication of the wealth of seasoned people that are currently present in the company. It is their extensive knowledge about Additive Manufacturing that has led Materialise to become the backbone of the 3D printing industry.

The story continued with many new meaningful innovations. From models, Fried made the decision to develop surgical guides and 3D-printed implants as well – initially in the dental field and general orthopedics.

Fried constantly pushed the boundaries of what the technology could do. When everyone was still using 3D Printing for prototyping, he went in a completely new direction with .MGX, partnering with world-class designers to come up with original designs for lamps, dresses, chairs – you name it.

Increasingly, his attitude turned towards combining the knowledge of Materialise with that of experts in other fields in order to create something daringly new. Together with Phonak, we turned around the entire hearing aid industry to create hearing aids which were produced more quickly and fit the customer better. Today we are doing the same in the eyewear industry with Yuniku – we are making eyewear which starts with a scan of the customer’s face and lenses and frames are then completely tailored to their anatomy and lifestyle.

[The Lily .MGX lamp]

All those years of innovation bring us here, to the present day, at TCT 2017. For the first time, TCT is hosting their Hall of Fame, which includes nominees from across the 3D printing industry who have made significant contributions to the field. Fried’s name was announced as one of the finalists, and this accomplishment is an immense honor, only increased by the pedigree of the other award winners. In Fried’s words,

“I have always believed that innovation is linked to value. So when I first encountered 3D Printing almost 30 years ago, I thought, here was something which could really add value to the way we make things.”

So what does the future look like for Materialise? It is clear that 3D printing technology is no longer an untested newcomer – it is capable of many wonderful, tangible things and the world is waking up to that fact. And just as Materialise was born from an idea, a vision on how a new technology could cause real change in the world, it will continue to grow and develop that technology in meaningful ways.